In the second step of his Upgrade Path, Russ explains how to go about upgrading your signal cables (that's interconnects and speaker cables to you and me). In this second part we cover speaker cables.

2.2. Signal Cables : Loudspeaker Cables

Technically, we are still at step 2: ‘Signal Cables’, as this includes both interconnects and speaker cables, but in some ways it’s useful to think of this as the third step, as it emphasises the need to leave your speaker cables to last.

I know this may sound odd to some, because speaker cables are often the first thing that comes to mind when the urge to upgrade strikes. However, important as speaker cables are, they should really come after you have upgraded the cables earlier in the chain.

There’s a simple reason for this: you can’t improve the signal that the speaker cable is given, and the better the speaker cable the more it will highlight that signal quality; good or bad.

The fundamentals of speaker cable design

There are four key features of speaker cable design to consider:

- Conductors

- Insulation (or dielectric)

- Terminations

- Geometry

Each of these elements is important as they will all have an influence on the performance of the cable. In the case of KIMBER KABLE®, geometry is the most fundamental part of the cable’s musical performance, so that’s where we’ll start.

KIMBER KABLE® Geometry

Radio Frequency Interference (RFI) is widely considered to be one of the most degrading influences on audio signals. This is especially the case with speaker cables because of the lengths involved; effectively, they are potentially acting as two huge aerials for RFI!

Most, if not all, speaker cable designs have some way of addressing this, commonly by the use of some sort of ‘shield’ wrapped around the cable.

Kimber’s solution is more fundamental; by braiding the cable in a specific way, so that the conductors counter-rotate and cross at the optimum angle, the design becomes a very bad aerial and thereby acts as a natural filter for RF noise.

This has a number of advantages over traditional designs, not least that it also mitigates RFI travelling along the cable from one component to another (traditional shielding only reduces RFI entering from the outside).

Kimber's 'counter rotated' woven geometry underpins their complete line-up of speaker cables. That’s great news, because it means you get the performance benefits of this tech right from the very first cable in the range.

Over the years, the design of individual cable ranges has developed, adapting and enhancing this woven structure, but the basic geometry is so fundamentally ‘right’ that it remains at the core of what Kimber do.

Conductors

There are two key points to consider here: the material from which the conductor is made and the quality, or purity, of that material.

Kimber offer three options when it comes to their range:

- High-purity Copper

- High-purity Copper/High-purity Silver Hybrid

- High-purity Silver

All the metals used in Kimber speaker cables are fine quality and get even better as you move up the range. Kimber only use pure copper and silver conductors - in our opinion, plating is generally a compromise leading to an unacceptable compromise in sound quality.

A note about silver

As a conductor material, silver has an unfair reputation for sounding harsh and aggressive. In our experience, this can be the case if the silver is not of a high enough purity or is used as a plating. Needless to say, Kimber only use the very best, pure silver in their conductors and the result is all the warmth and musicality of copper but with added insight and sound-staging.

VariStrand™

In addition to high-quality materials and purity, Kimber also add another dimension to conductor design. All cables in the range from PR upwards feature Kimber’s proprietary VariStrand™ conductors.

Different gauge wire tends to favour different frequencies: for example, large strands favour lower frequencies and smaller strands favour higher frequencies.

Most speaker cables use conductors of the same size, or gauge, and could therefore be said to favour a narrower bandwidth.

Most speaker cables use conductors of the same size, or gauge, and could therefore be said to favour a narrower bandwidth.VariStrand™ conductors, on the other hand, are made up of a number of individual strands, each varying in size, to give a more natural balance.

Combined with Kimber's unique woven design this makes for a very high performance cable design, suited to any level of system from budget to high end.

Insulation

The cable insulation - or dielectric - naturally absorbs a certain amount of energy. This can degrade the signal because some of that energy gets released back into the cable causing small time delays. This process, called dielectric absorption, can be reduced by the choice of material used and this, in turn, will have a positive effect on sound quality.

As you move up the range, Kimber speaker cables progress from the use of polyethylene (the PR models) to the very best fluorocarbon or Teflon® (4TC and higher).

Of special note are the Carbon cables, which use a carbon-infused polymer between the conductors and the insulation. This locks the conductors in place, improves conductivity and improves the performance of the insulation on top.

Termination

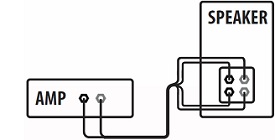

The final important aspect of your speaker cable is the type and quality of connector. It stands to reason really: this is the vital point at which the signal is transferred, from the amp to the cable and from the cable to the speaker, so there is potential for part of the signal to be lost or degraded. Ensuring a good, clean connection is therefore paramount to achieving the best performance from your speaker cable.

The final important aspect of your speaker cable is the type and quality of connector. It stands to reason really: this is the vital point at which the signal is transferred, from the amp to the cable and from the cable to the speaker, so there is potential for part of the signal to be lost or degraded. Ensuring a good, clean connection is therefore paramount to achieving the best performance from your speaker cable.Which termination do we recommend?

There is an argument to say that the best option are spades because they have a wider surface area to connect with the binding posts on your amp and speakers. The problem is that in order to ensure this connection remains good, you will have to check and tighten the posts on a regular basis, otherwise, as they inevitably loosen, the connection will degrade.

In addition, because they are more open to the air, you will need to clean them more often to reduce oxidation. For these reasons, we recommend the use of high quality banana plugs.

We offer the following options for terminating your cable:

- Cut and stripped – the least expensive and straightforward option. Ideal for ‘spring-clip’ terminations and for those on a budget. Available on all cables up to 8TC.

- Kimber bananas – our most popular connection. Easy to use and provides an excellent, consistent connection. Available on all cables up to 12TC, Carbon 8 and Carbon 16.

- Kimber spades – Kimber’s PostMaster spades offer an excellent connection where banana sockets are not available or you are happy to maintain them through choice. Available on all cables up to 12TC, Carbon 8 and Carbon 16.

- WBT spades and bananas – the best! Available in copper or silver versions; we don’t know of a better connection. Available as standard on Monocle XL and above.

- BFA – these connections are available for those with certain models of Cyrus and Linn amplifiers.

Choosing the right cable for you

We don’t tend to recommend particular Kimber cables for specific brands of Hi-Fi equipment: Kimber Kable is very natural and neutral, so no model in the range will favour one particular brand or type of amplifier over another (apart from some much older Naim gear - contact us for advice - most Naim models go very well with Kimber).

In general, our advice is to buy the best cable your budget will allow at the time, keeping the following points in mind:

For example, buying Monocle XL to use with YellO PowerKords and Tonik interconnects would not be good value - go back and improve the first two steps first before upgrading to this level of speaker cable.

In this example, I would probably say you should have a minimum of Evolution-300 PowerKords, X-Block and Hero-HB before considering Monocle-XL.

2. Our Cable Upgrade Scheme is there to help you move up the range as painlessly as possible.

2. Our Cable Upgrade Scheme is there to help you move up the range as painlessly as possible.Whatever cable you buy from us can be used to trade-in against the same type of cable, higher up the range, at a later date - you’ll get a minimum 50% of the cost back (2+ years old) and a maximum of 100% (up to 12 months old) - see full terms and details of our Upgrade Scheme here.

3. Our 60-Day Money-Back Guarantee allows you to trial your new cable in your own system, in your own room, because this is the only relevant way to discover how well the cable performs for you.

We give you 60 days so that you have time to hear how the cable will sound once it’s burnt-in.

If you’re undecided between two models, we’re happy for you to buy both and compare them on the same basis - then return the cable you don't want. For full details of our money-back guarantee click here

The Burn-in period

Any cable - whether our own or from another brand - will change over time as a signal is passed through it. This ‘settling-down’ or Burn-in period can take up to 500 hours to fully complete and can often make a huge difference to the sound of the cable.

We advise taking full advantage of our 60-day trial period to ensure you have a better idea of how the cable is going to sound in the long term.

We offer a Burn-in service for £15 - this will speed up the natural process so that the cable should be settling into your system by a couple of weeks.

Our ProcessQ™ is a very different beast. This is a unique, sophisticated process that is applied to the cable to boost its inherent capabilities - it improves the cable performance, whereas standard Burn-in simply speeds up the natural process. ProcessQ™ is available on all speaker cables for £199.

RF Zapperators™

The point at which a speaker cable terminates into the speaker – or from the amp – is particularly vulnerable to RFI and can potentially allow noise into the audio signal.

We believe that Kimber speaker cables already go a long way to rejecting this because of their unique woven design. Nevertheless, this connection point could still be vulnerable to RFI and this is what RF Zapperators are designed to address.

RF Zapperators use a network of specialised, very high specification components to stably absorb residual RF and further reduce noise at speaker cable terminations. They tend to be most effective at the speaker end but can also be used on amplifier binding posts - try them in both and see which works best for you.

Find out more about RF Zapperators

Bi-wiring

It’s very easy, and understandable, to assume that because a speaker has two sets of binding posts it will sound better bi-wired, but this is far from the whole story. Don’t get us wrong; bi-wiring can sound better, but it’s not a given that it will and, through years of experience, we’d advise single-wiring. Here’s why:

One of the key benefits of bi-wiring is that doubling the cable can halve the impedance which will potentially bring sound improvements, especially in the bass. However, in many circumstances this can also be achieved by moving up to a better quality single-wired cable.

For example, moving from 4 to 8TC doubles the conductors, giving you the equivalent of bi-wiring with 4TC. On paper, there is nothing to choose between these options; same number of the same conductors. But there is an important difference because having all those conductors in the one cable also affects the complexity of the woven geometry, making it a better filter for RFI.

In our experience, this has invariably brought a bigger benefit, so the advice is to put your money into a better cable and use a high quality set of Jumper cables.

If you do decide to bi-wire - for example, the speaker manufacturer may recommend this for a specific model - Kimber have a couple of high-quality options made specifically for this purpose:

If you do decide to bi-wire - for example, the speaker manufacturer may recommend this for a specific model - Kimber have a couple of high-quality options made specifically for this purpose:Find out about Kimber Bi-wire cable

Jumper Cables

Most speakers provide ‘links’ to connect the two sets of binding posts when you are single wiring biwirable loudspeakers; these links can sound terrible and may well be the reason some people report improvements in sound quality when they bi-wire – simply because they’ve removed them!

Our jumper cables enable you to replace these links with high quality Kimber cable and the difference in sound quality can be quite dramatic. We offer three ranges: TC Jumpers, utilising Kimber 4TC and 8TC cable, Carbon Jumpers featuring carbon-infused Kimber cable and Kimber Select jumpers for high-end applications.

Find out more about jumper cables

The KIMBER KABLE® Range

Here’s a brief round-up of the complete range of Kimber speaker cables.

Click here for more about the KIMBER KABLE® range of speaker cables.

The 4, 8 & 12 series - all feature Kimber’s unique counter opposed helical braid. Additional conductors (4, 8 & 12) make for a more complex weave.

The Monocle Series - enhances the basic woven geometry by braiding and spacing different types of copper conductors around an inner core to improve the woven design.

The Carbon Series - the newest family of speaker cables feature Kimber’s new Carbon Infused technology, which uses a carbon polymer to lock the VariStrand copper conductors in place. Three models: Carbon 8 and 16 & Carbon 18XL.

The Select series - The top-of-the range Kimber Select series of cables enhance the spaced-and damped construction, creating a more effective, highly-complex weave. Three variants: KS- 6063, KS-6065 and the flagship KS-6068.

BACK... to Step 2.1. Signal Cables: Interconnects

Written By Russ Andrews